Finding better solutions to use energy efficiently

Preface

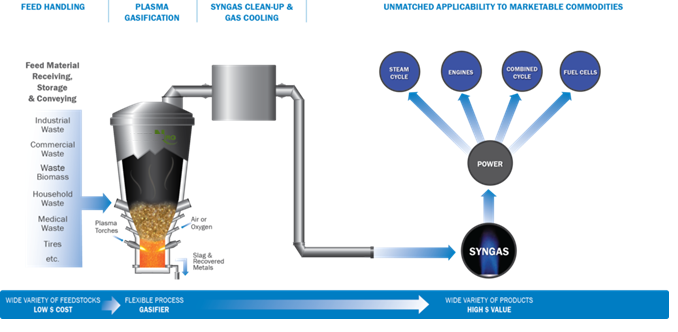

By using biomass power generation solutions it is possible to manage the different types of waste more effective. Using Micro-turbine in the power plant make the solution more feasible and cost effective and also nature friendly.

Figure 1 : Biomass Power Generation Process

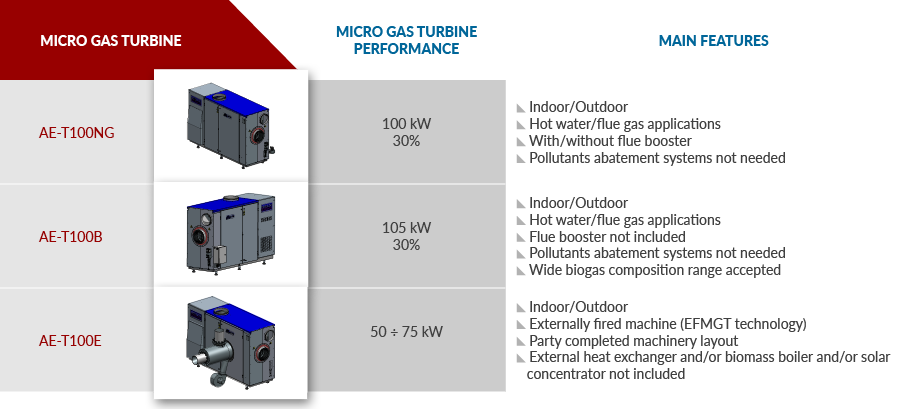

Ansaldo Energia Turbec is an innovative solution which can feed with the gasification of externally fired technology (Microturbine in EFGT configuration).

The Turbec AE-T100E is suitable for this type of application in combination with an External plasma chamber and some interface and pre-generation heat-exchanger.

Figure 2 : Different types of Micro-Turbine

In an E-Model the overall output of the system is 75KW of electricity.

The solution

The powerplant solution includes the following technological divisions. That the Power island of the plant will be manufactured and implemented by AEN[1] and the other parts can be provided and implemented by GEKO S.P.A with cooperation of AEN-I[2].

- 100KW+200KW Microturbine with EFGT Technology

- Biomass Chamber

- Mediator heat exchanger

- Water heater from exhaust

Figure 3 : Power Block Diagram

AE-T100 Externally Fired Micro Turbine

The EFGT (Externally Fired Gas Turbine) version of the AE-T100, also called "AE-T100E" is a system that derives from a partly completed standard AE-T100 by replacing the combustion chamber with a special piping assembly that enables the connection with a high temperature heat exchanger, installed inside the external boiler(*).

The system has been designed to combine all the advantages of a micro gas turbine with the opportunity to exploit different energy sources as, for instance, biomass burner or solar concentrator.

The use of an external boiler allows to obtain the thermal energy required to operate the gas turbine from the combustion of different sources of biomass (wood, forest waste, animal manure, sewage sludge, etc.)

The final system is therefore essentially composed by an external boiler(*) that uses a high-temperature heat exchanger(*) to transfer the thermal energy to a micro gas turbine, that operates in an open "Brayton" cycle.

Due to the split-up between combustion and evolving fluid (air), this system allows the use of solid fuels/waste fuels otherwise not usable in small size plants based on gas turbines.

The low maintenance requirements of the AE-T100E, with service intervals of 6,000 operating hours, makes this power generation system extremely attractive and competitive when compared to more conventional solutions.

Each AE-T100E configuration can be delivered in specific layouts for indoor or outdoor installation. Both layouts meet current regulations limits for noise and emissions. All AE-T100 can be remotely monitored, controlled and operated.

Feasible Approach

There are some financial, support and quality policies which should be considered prior to bring the complicated EFGT model to Iran.

The following policies are the most important ones.

- Minimum amount of installed Microturbines in Iran territory should be 200 to be confident that support needs and policies can be met and as there is no previously installed system in the territory a special organization needed to start vendor negotiations.

- Prior to approach to the vendor the Iranian IPP should be well established and all certificates for Powerplant should be acquired and FS should be prepared. Then an international consultant need to be involved in this early stage.

- As at this moment the important issue is the financial issue then it is crucial that all financial vehicles for this project should be organized and safe channel should be considered.

- The suggested organization that is suitable for using international technological facilities can be as front picture :

Figure 4 : Execution and Operation Organization

[1] Ansaldo ENergia

[2] AEN-Iran